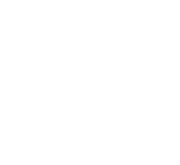

Remotely Monitor Connectivity

Remotely monitor device and PLC connectivity and proactively resolve issues to safeguard from critical data loss and unplanned downtime.

Connect disparate factory devices and machines for real-time visibility into production status, data connectivity, maintenance issues, operational efficiency, product quality, and other critical performance indicators.

BENIFITS

- Efficient root-cause analysis for faster issue traceability, troubleshooting, and resolution

- Enhanced insights into connectivity errors

- Reduced unplanned downtime

- Increased flexibility through enhanced remote capabilities

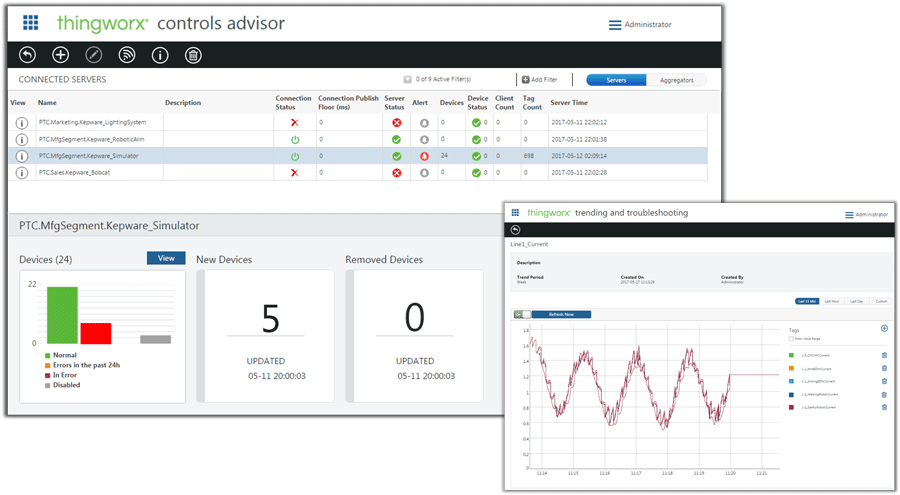

Remotely Monitor your Production

Access real-time production line and machine data for immediate root-cause analysis and proactive resolution of performance issues.

Visualize real-time production data with customizable dashboards that empower workers to meet production goals. Identify bottlenecks using deep analytics provided by numerous reports such as OEE, cycle analysis, machine utilization, and downtime history that enables production managers to make more informed and confident decisions.

BENIFITS

- Improved data-driven decision-making for optimized performance

- Efficient and accurate root-cause analysis of performance issues

- Increased responsiveness to problems in production lines and assets

- Streamlined high-level benchmarking of lines and assets

- Improved communication and performance awareness between the shop floor and the top floor

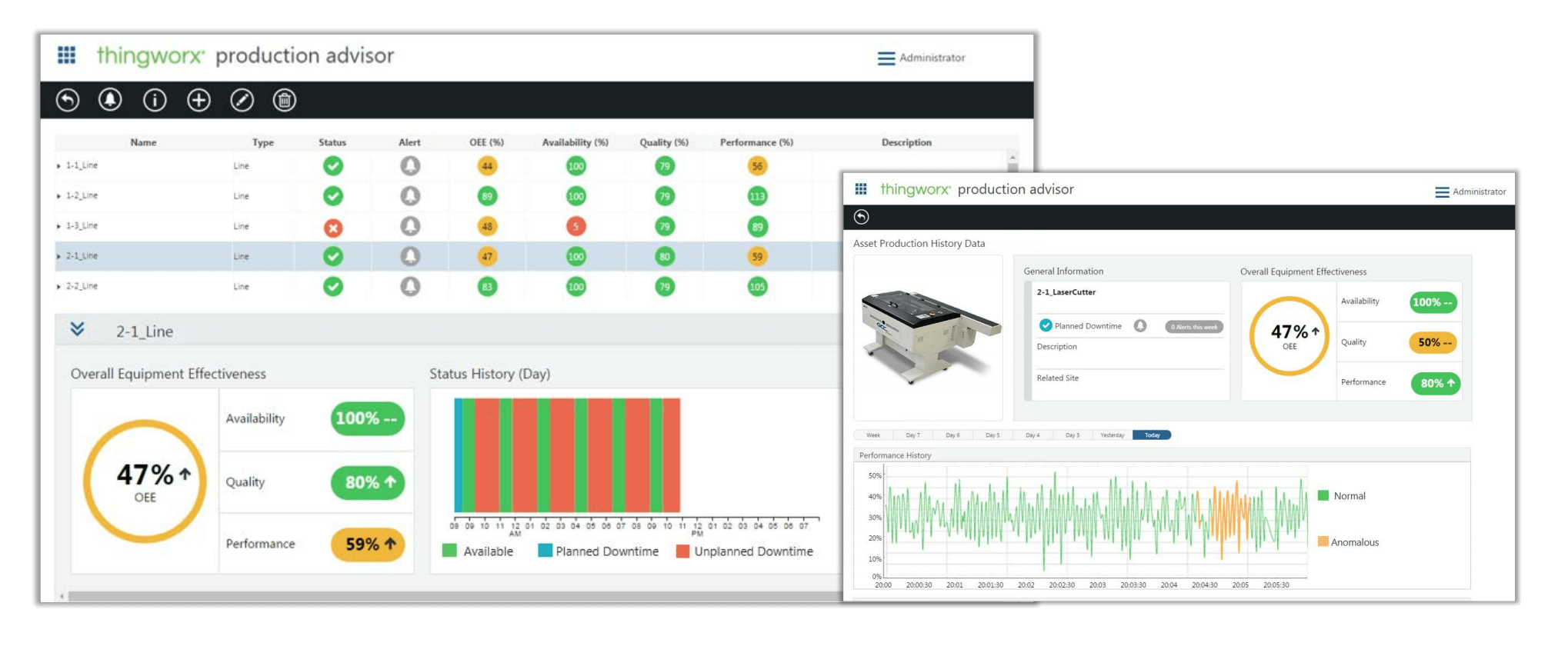

Remotely Monitor Equipment

Remotely monitor assets in real-time, automatically detect anomalies, and correct potential issues before they impact production.

Monitor your equipment in real-time, receive alerts when anomalous behavior occurs, manage preventative maintenance schedules and be alerted when maintenance is due. Track equipment utilization over time to manage capacity. Configure alerts based on any machine condition or alarm. Optimize tool life with detailed analytics and reports. Designed specifically for CNC Machine Tools.

BENIFITS

- Faster and more informed maintenance planning, decision-making, and execution

- Proactive issue identification for reduced unplanned downtime

- Real-time visibility into patterns and trends

- Reduced scrap and rework

- Improved process efficiency and prouct quality

Leave your automation vision to us. Focus on the Profits.

Mac India is the most Respected partner for Automation and System Integration